Yes, it is generally possible to choose a preferred delivery date. Please inform us of your desired date during the order process or as early as possible. We will then check availability and confirm the date if feasible. If your preferred date cannot be met, we will suggest a suitable alternative to ensure your delivery or service meets your needs.

Frequently Asked Questions (FAQ)

Welcome to our FAQ section!

Here you will find answers to the most common questions about our products, services, and processes.

In addition, we provide useful tips and insights related to the beverage industry.

Our goal is to help you quickly and easily. If your question is not answered here, please do not hesitate to contact us directly – we are happy to assist you personally.

Ordering, delivery & shipping

How do I handle complaints?

If you have a complaint, please contact our customer service team directly. Please have all relevant information ready, such as your order number, invoice details, and the machine’s serial number. Our team will review your request as quickly as possible and get in touch with you to provide a suitable solution. Depending on the situation, this may include a repair, replacement, or refund. Our goal is to handle your complaint efficiently and to your complete satisfaction.

Is it possible to choose a preferred delivery date?

Can I track my shipment?

Which shipping providers does WTG-Quantor work with?

WTG-Quantor cooperates with trusted and well-known logistics partners to ensure safe and timely delivery. Depending on the order size and destination, we ship via DPD, UPS, DHL, or DACHSER.

This guarantees that every shipment – from spare parts to complete systems – arrives quickly, safely, and on schedule.

What is the product availability?

The availability of our items depends on the specific product. Many of our standard models are available at short notice, while customized systems or special configurations are available upon request.

We also maintain a large stock of spare parts, enabling quick and reliable delivery in most cases.

For detailed information about availability and delivery times, please contact our sales team.

What is the warranty period for Quantor cooling units?

The warranty period is 12 months from commissioning, but no longer than 18 months from delivery of the unit. The warranty covers replacement parts only.

For warranty cases outside Germany, any shipping or transport costs for spare parts or equipment, as well as any travel expenses, will be charged separately.

Company & Services

What sets QUANTOR apart from other manufacturers?

QUANTOR stands for top quality, innovative technologies, and tailor-made solutions. Unlike many other manufacturers, we combine decades of experience in refrigeration and climate control with a deep understanding of our customers' specific needs. Our focus is not only on developing high-performance products but also on providing comprehensive consulting, personal service, and sustainable concepts. This results in solutions that are precisely tailored to individual requirements – efficient, reliable, and future-proof.

Is WTG‑Quantor active internationally, and how is distribution handled abroad?

What services does WTG‑Quantor offer after purchase?

How does the planning, design, and commissioning of new systems work?

How does project execution work?

Why choose WTG-Quantor products?

At WTG-Quantor, every machine we build and every component we select is designed with one clear focus: to meet the specific requirements of wine, beer, spirits, and beverage production. Our engineering and automation systems are developed exclusively for these applications – ensuring precision, efficiency, and quality at every stage of production.

Unlike many other manufacturers who primarily focus on air-conditioning, our expertise lies in process cooling and temperature control tailored to the beverage industry.

Furthermore, our well-structured commercial and technical network is always at our customers’ disposal, providing immediate support and competent advice whenever needed.

With this dedication, WTG-Quantor GmbH stands today as the most reliable, efficient, and safe partner for temperature control solutions in beverage production.

Produkte, technische Systeme und Anwendungen

What is the VinInfo system and what is it used for?

What is the advantage of digital fermentation control?

Advantages of Digital Fermentation Control – Precision, Efficiency and Maximum Process Reliability

Digital fermentation control takes your production process to the next level. It combines state-of-the-art sensor technology, intelligent control algorithms and automated process management to make fermentation as precise and efficient as possible.

Precision through intelligent sensor technology

High-resolution temperature and process sensors continuously monitor conditions inside the tank.

The digital control system reacts in real time and maintains the target temperature within a few tenths of a degree – a decisive advantage for aroma development, color formation and overall product quality.

Automated control using modern algorithms

In the background, adaptive control algorithms apply cooling or heating exactly when required.

The result: stable fermentation processes, reduced energy consumption and significantly lower temperature fluctuations.

Full transparency through data recording

All values – from temperature curves and fermentation progress to CO₂ development – are fully documented.

This allows you to:

Track production steps

Reproduce batches

Optimize quality parameters over the long term

Remote monitoring and mobile control

You can access your systems at any time via PC, tablet or smartphone, including:

Live monitoring

Alarm notifications

Adjustment options for tanks and recipes

This ensures full control wherever you are – and maximum process safety for your fermentation.

Energy-efficient and resource-saving

Intelligent control activates cooling circuits only when they are actually needed.

This minimizes energy consumption and extends the service life of the system components.

How many tanks can I control with one system?

With the modular control and cooling systems from WTG-Quantor, you can precisely control any desired number of tanks — from individual tanks to entire fermentation cellars. Our technology is specifically designed to meet the requirements of wineries, breweries, cider producers, and other manufacturers of fermented beverages, providing reliable and energy-efficient temperature and process control.

Single-tank controllers such as FermFix and FermFlex are ideal for individual tanks and offer precise temperature regulation with optional software control. For larger installations, our central control cabinets, such as the FermFlex-Box, are available and can monitor and control 10, 20, or 30 tanks simultaneously.

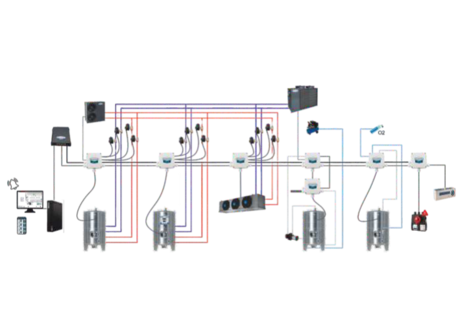

For professional production facilities, our BUS systems (e.g., VinInfo) offer a scalable complete solution that integrates virtually unlimited numbers of tanks. In addition to temperature control, further processes such as CO₂ monitoring, tank level measurement, pump control, oxygen dosing, and much more can be integrated — perfect for a fully connected and automated production environment.

In short:

WTG-Quantor provides tank control that grows with your operation, offers maximum process reliability, and adapts precisely to your production requirements.

Contact us — we will work with you to plan the optimal solution for your facility.

Can Quantor chillers be placed outside in the rain?

It depends on the type of Quantor chiller.

The following series cannot be exposed directly to rain: MiniChilly, IceChilly, ModuChilly, Chilly, Chilly Max, MCK, KreyoPack, and SR.

If these models are installed outdoors, a protective shelter is required. The shelter roof should be at least 2 meters above the fan and extend 1 meter around the unit to allow proper airflow and prevent water damage.

All other Quantor chiller series are weather-resistant and can be safely installed outdoors without a shelter, even under rainy conditions.

What is the difference between the MCK series and the Quantor Pro series?

Both the MCK series and the Quantor PRO series offer outstanding cooling performance and reliability. The right choice depends on the application and installation environment.

The MCK series is ideal when a larger buffer tank and an open water circuit are preferred. For example, the MCK 321 (38.6 kW) includes a 300-liter tank, offering greater temperature stability and easier handling – especially suitable for small to medium-sized wineries and breweries.

The Quantor PRO series, on the other hand, features a closed water circuit, which is more energy-efficient and better suited for automated or temperature-sensitive systems. It’s the perfect choice for larger installations or when process precision is critical.

What is the recommended propylene glycol percentage in water for a -10°C outlet temperature?

For a chiller system with a solution outlet temperature of -10°C, the recommended propylene glycol concentration is 33% glycol and 67% water by volume. This ratio provides effective frost protection, stable cooling performance, and optimal heat transfer efficiency.

The best way to verify the glycol-water mixture is by using a refractometer designed for antifreeze solutions. Refractometers intended for sugar measurement (Brix) are not suitable for this purpose.

WTG-Quantor offers high-precision antifreeze refractometers to ensure accurate glycol mixture readings. Please contact our team for product information and pricing.

What are the most important factors affecting a chiller’s cooling capacity?

Several key factors influence the cooling capacity and efficiency of a chiller. Understanding these factors helps ensure optimal performance, energy savings, and system reliability.

1. Ambient temperature and water inlet/outlet temperatures

According to IS 16590 international standards, chillers are rated at 35 °C ambient temperature and 12 °C / 7 °C water inlet/outlet. When the ambient temperature is higher, or the water temperature difference is smaller, the chiller cooling capacity decreases.

2. Installation environment and ventilation

Installing a chiller in a poorly ventilated area limits air circulation and reduces heat dissipation efficiency. Proper airflow around the condenser is essential to maintain stable performance.

3. Condenser cleanliness and air quality

Dust and dirt on air-cooled condensers block heat exchange, forcing the compressor to work harder. Regular maintenance and cleaning preserve chiller performance and lower energy consumption.

For maximum cooling efficiency, always ensure proper installation, good ventilation, and scheduled maintenance in accordance with the manufacturer’s recommendations.

What efficiency gains can be achieved with modern control technology?

Modern control technology significantly improves the efficiency of cooling, fermentation, and production processes. With precise temperature control, advanced sensors, and automated process management, wineries, breweries and beverage producers can reduce energy consumption, operating costs, and production risks.

Key efficiency benefits of modern control systems:

Lower energy consumption thanks to precise, demand-driven temperature regulation

More stable fermentation with consistent temperature control

Automation of cooling circuits, valves, pumps and CO₂ monitoring

Optimal chiller performance and load distribution during peak fermentation

Data logging, monitoring and analytics for continuous process optimisation

Early-warning alarms and notifications increase reliability and prevent downtime

Modern control technology delivers higher efficiency, improved product quality, and safer production processes – a major advantage for any temperature-sensitive beverage production.

What are the benefits of CO₂ monitoring during fermentation?

CO₂ monitoring is a key component of modern fermentation management and plays a vital role in safety, process optimization, and product quality in wineries, breweries and beverage production facilities. During alcoholic fermentation, large amounts of carbon dioxide are produced – an invisible, odorless and heavy gas that can accumulate unnoticed without appropriate monitoring.

Advanced CO₂ sensor technology helps prevent dangerous conditions while providing valuable real-time insights into the fermentation process.

1. Maximum safety for your team

CO₂ can quickly reach harmful levels in cellar environments. Continuous monitoring ensures:

automatic alarms when thresholds are exceeded

protection from CO₂ exposure and oxygen displacement

compliance with workplace safety regulations

safe working conditions at all times

2. Accurate fermentation tracking

CO₂ output is a direct indicator of yeast activity. Monitoring provides:

real-time insight into fermentation progress

reliable detection of slowdowns or fermentation completion

early identification of irregularities

consistent, reproducible process control

3. Optimized temperature and process management

CO₂ data combined with temperature control allows:

precise cooling based on actual fermentation activity

significant energy savings

prevention of fermentation issues

reduced manual monitoring

4. Higher product quality

Stable, well-controlled fermentation results in:

cleaner flavor profiles

consistent batch quality

improved aroma development

reduced microbial risks

5. Digital, future-ready production

Modern CO₂ systems integrate seamlessly into control and software platforms, enabling:

trend analyses

automated documentation

full process transparency

smart decision-making

Conclusion:

CO₂ monitoring enhances safety, efficiency, and product quality—making it an essential tool for every modern winery, brewery or fermentation facility.

Which beverages can I control with WTG-Quantor systems?

WTG-Quantor’s cooling and fermentation control systems are designed for the entire beverage industry and can be used in nearly every production environment. With precise temperature control, powerful chilling technology and advanced digital regulation, our systems are suitable for all major fermented and temperature-sensitive beverages — from small craft producers to industrial facilities.

Our systems can reliably control the following product categories:

Wine

White, red, rosé

Must cooling

Fermentation control, cold stabilization, storage temperature

Optional CO₂ monitoring and oxygen dosing

WTG-Quantor is an international market leader in process cooling for wineries.

Beer

Brewhouse, fermentation, lagering

Conditioning, diacetyl rest, cold crash

Ideal for both craft breweries and large-scale beer production.

Cider & Fruit Wines

Fermentation and clarification temperature control

Stable cooling for clean, balanced aromas

Perfect for cideries and fruit wine producers.

Distillates & Spirits

Mash fermentation for whisky, rum, gin, fruit brandy

Cooling for distillation and condensation processes

Temperature control for optimized flavor development

Entire Beverage Industry

Also suitable for:

Soft drinks

Kombucha & fermented beverages

Tea & coffee extracts

Dairy and mixed beverages

Cannabis-infused drinks

Functional drinks & specialty ferments

Thanks to modular systems and flexible control technology, both single tanks and large tank farms or full production lines can be managed efficiently.

Why are WTG-Quantor systems suitable for so many beverage types?

Precise temperature control from –10 °C to +40 °C

Reliable indoor and outdoor operation

Smart controllers (FermFix, FermFlex, VinInfo, BUS systems)

Industrial-quality components

Fully compatible with tanks from any manufacturer

Centralized or decentralized control options

Contact us — we will design the perfect solution for your beverage production.

Industry Knowledge & Application Benefits

What happens if wine ferments at too high a temperature?

If wine becomes too warm during fermentation, it can negatively affect the production process. High temperatures may speed up fermentation but often result in the loss of delicate aromas and an unbalanced flavor profile. Yeasts can become stressed or die, causing fermentation to stop and quality to deteriorate. Unwanted off-flavors or faults may develop. This is why precise temperature control is essential for quality and stability of the final product.

Why must wine be cooled during fermentation?

During fermentation, heat is generated as yeast converts sugar into alcohol and carbon dioxide. If the temperature rises too much, delicate aromas can be lost, fermentation can become unbalanced, or the yeast may die. Controlled cooling keeps the temperature at an optimal level, ensuring steady, aroma-preserving fermentation. The result is wines with a clear, harmonious flavor and high quality.

Can I also use the cooling systems for cannabis?

Yes, our cooling systems are also suitable for use with cannabis products. WTG-Quantor has been developing precise and reliable temperature control systems for many years, and today offers comprehensive solutions specifically designed for the needs of the cannabis industry.

Our equipment supports all key process steps – from cultivation and room climate control to advanced cannabis extraction. These include, among others:

- Safe and precise temperature control for cannabis extracts such as THC, CBD, or CBN

- Preservation of terpenes and cannabinoids through stable, low process temperatures

- Prevention of contamination (waxes, lipids, chlorophyll) through exact temperature control

- Cooling of CO₂ extraction systems, pumps, and other process hardware

- Support for solventless methods like Ice-Water-Hash/Bubble-Hash

- Climate control and humidity regulation in grow and drying rooms using Fan Coils and HumiSys systems

Our solutions are designed for both small laboratory setups and large-scale productions.

In short: Yes – our cooling systems are perfectly suited for cannabis products.

What role does storage cooling play in the maturation of beer, wine, and spirits?

Proper storage cooling plays a crucial role in the maturation, stability, and quality of wine, beer, and alcoholic beverages. After fermentation, the storage and aging phase begins—a decisive period during which flavor, aroma, clarity, and shelf life are shaped. A constant, precisely controlled storage temperature is essential to optimally support the natural maturation process.

Storage Cooling for Beer: Maturation, Clarity, and Flavor

For beer, controlled cooling during storage is particularly important. During maturation, yeast cells break down remaining by-products such as diacetyl (buttery flavor) or acetaldehyde (green apple notes). A stable storage temperature between 4–8 °C ensures that this process proceeds slowly and evenly, without compromising aroma or freshness.

Cold storage also promotes the natural precipitation of haze-forming substances such as proteins, polyphenols, and yeast, resulting in clearer and more visually appealing beer. Carbonation binds more effectively as well, leading to balanced effervescence and a pleasant mouthfeel. For breweries, this means a final product that is not only sensorially stable but also meets high visual quality standards.

Storage Cooling for Wine: Aroma, Structure, and Shelf Life

Precise temperature control during storage is equally critical for wine. Fluctuating or excessively high temperatures can accelerate aging, promote oxidation, and hinder the development of delicate aromas. Uniform storage at around 10–12 °C allows the characteristic notes of red, white, and sparkling wines to develop harmoniously.

In addition, constant cooling preserves the wine’s structure, maintains acid balance, and prevents premature loss of freshness. High-quality wines in particular benefit from slow, controlled aging, which can only be achieved under stable storage conditions.

Storage Cooling for Spirits, Cider, and Mead

Spirits, cider, and mead also benefit from optimal storage conditions. Low, stable temperatures reduce chemical reactions, prevent oxidation, and help preserve aromas and freshness over extended periods. Precise storage cooling directly impacts sensory quality and extends the shelf life of these beverages.

Benefits of Professional Storage Cooling

Consistent quality: Stable temperatures ensure reproducible batches and consistently high product standards.

Optimal aroma development: Cooling allows aromas to mature harmoniously while reducing unwanted by-products.

Clarity and stability: Proteins, yeast, and haze particles settle efficiently, resulting in visual appeal and flavor stability.

Extended shelf life: Controlled storage preserves freshness and longevity.

Economic efficiency: Producers benefit from reduced waste, stable quality, and improved storage capability.

Conclusion

Proper storage cooling is a key quality factor in the production of wine, beer, and alcoholic beverages. It ensures optimal maturation, protects aromas, improves clarity and stability, and extends shelf life. Modern cooling systems enable precise temperature control and are therefore indispensable tools for breweries, wineries, and producers of premium alcoholic beverages. Those who invest in stable, controlled storage ensure that every beverage reaches its full sensory potential and delivers the highest quality to consumers.

What is the significance of temperature in the production of wine, beer, and other alcoholic beverages?

Temperature is one of the most important quality factors in the production of wine, beer, cider, spirits, and all other fermented beverages. Precise temperature control determines how stable the fermentation process is, how cleanly the yeast works, and how intensely aromas, color, and structure develop. Anyone who wants to produce high-quality beverages therefore needs reliable and precisely controllable fermentation and cooling technology.

Excessively high temperatures often lead to unwanted off-flavors, yeast stress, and uncontrolled fermentation. Temperatures that are too low slow down fermentation or bring it to a complete halt. The right temperature window is therefore essential for product quality—whether white wine, red wine, lager beer, ale, cider, or distillation mash.

The right temperature not only influences fermentation, but also maturation, stabilization, and storage. Only constant, hygienically safe, and energy-efficient cooling can protect aromas, reduce microbiological risks, and ensure consistent product quality.

Modern digital control technology—such as the systems from WTG-Quantor—enables highly precise control of tank temperatures, CO₂ output, and process data in real time. This ensures reproducible results, lower energy and operating costs, and maximum process reliability. For winemakers, brewers, distilleries, and the entire beverage industry, professional temperature control is an indispensable part of a quality strategy.

What is the ideal fermentation temperature for white wine and red wine?

The ideal fermentation temperature depends largely on whether white or red wine is being produced and on the chosen fermentation style. For white wine, winemakers often use cool, controlled fermentation. At temperatures around 14 to 16 °C, fermentation progresses slowly and steadily: the yeast converts only about 10 to 15 g/L of sugar per day, equivalent to 4 to 5° Oe. When the temperature is raised slightly to 18 to 20 °C, the process accelerates noticeably, with 20 to 30 g/L of sugar (about 8 to 10° Oe) being metabolized daily. This careful temperature management helps preserve freshness, aroma and balance.

Red wine behaves similarly but is generally fermented at higher temperatures. A moderate fermentation between 20 and 23 °C results in a steady conversion of about 20 to 30 g/L of sugar per day, equal to 8 to 10° Oe. In contrast, a warm fermentation at 25 to 28 °C significantly increases yeast activity, often reaching 50 g/L of sugar per day or more, which corresponds to at least 20° Oe. These higher temperatures not only boost fermentation speed but also enhance the extraction of color, tannins and aromas from the skins – essential for producing structured, full-bodied red wines.

These differences clearly show how strongly temperature influences fermentation and why precise temperature control is crucial for each wine style. By guiding the process carefully, winemakers can achieve more reliable fermentations and higher-quality wines.

What influence does temperature have on the fermentation process?

Temperature is one of the key factors that determine both the progression and the outcome of the fermentation process. It directly affects yeast activity, aroma development, the speed of sugar breakdown, and ultimately the quality of the wine. In general, the rule is: the warmer the fermentation environment, the more active the yeast works – and the cooler it is, the slower and more controlled the fermentation proceeds.

At low temperatures, fermentation remains calm and steady. The yeast converts sugar slowly, resulting in more delicate aromatic expression, which is particularly characteristic of white wines. Cooler conditions promote fruity, clear, and elegant aromas because volatile compounds are better preserved during fermentation.

When the temperature increases, the fermentation process accelerates significantly. The yeast metabolizes more sugar per day, and the wine develops more quickly. At the same time, the extraction of compounds from the grape skins increases – an advantage for red wines, where color, tannins, and structure are essential. However, excessively high temperatures pose risks: yeast stress, unwanted by-products, and loss of valuable aromas.

A stable and well-controlled fermentation temperature is therefore essential. It prevents fermentation problems, protects against off-flavors, and allows the winemaker to precisely shape the desired wine style. Temperature is thus one of the most effective tools for influencing wine quality, character, and expression.

How can I control the fermentation temperature in my winery?

In modern wineries, the most reliable way to control fermentation temperature is through digital control and cooling systems that automatically monitor the entire fermentation process and precisely cool or heat the tanks. The goal is to maintain a stable, optimal temperature inside the tank so the yeast works cleanly and produces the desired aromas.

One of the most efficient solutions is the VinInfo system from WTG-Quantor – a modular digital control, regulation and information system specifically developed for wineries.

How does temperature control work with the VinInfo system?

VinInfo continuously measures the actual tank temperature and automatically adjusts cooling or heating. The system manages all essential functions, including:

- Precise temperature monitoring for each individual tank

- Automatic regulation of fermentation temperature (cooling/heating)

- CO₂ monitoring to analyze and control fermentation progress

- Tank level measurement via radar sensors

- Control of pumps, valves and refrigeration units

- Time-controlled processes such as acidification, yeast addition and mixing

- Full digital documentation of all fermentation data

- Email alerts in case of temperature deviations

This ensures that each tank remains exactly within the desired temperature range — whether for cool-fermented aromatic white wines or for warm, structured red wine fermentations.

Why is VinInfo especially suitable for wineries?

- Modular and scalable: from small estates to large winery operations

- Control of an unlimited number of tanks

- Central operation of all tanks, systems and pumps

- Graphical evaluation of the entire fermentation process

- High process reliability and reproducible wine quality

- Significantly improved energy efficiency

This makes fermentation management safer, more stable and much easier to handle.

Conclusion

The best way to control fermentation temperature in a winery is to use a digital, fully automated regulation system. With VinInfo, WTG-Quantor offers one of the most advanced solutions on the market—ensuring maximum quality control, consistent results and energy-efficient wine production.

The WTG sales team supports wineries in planning complete installations with tailor-made solutions for the wine and beverage industry and advises on adapting technical equipment to the specific requirements of each production site.

Maintenance & Support

How does remote maintenance work, and how can I obtain the tool?

With Quantor Remote Support for the VinInfo system, you receive fast and reliable assistance for your fermentation control. In the event of a support request, our experts connect to your system via remote access and resolve technical issues in real time—without the need for an on-site visit. This saves time and minimizes downtime.

The remote support tool can be easily downloaded via the provided download link. Once the tool is launched, our support team can connect to your system securely and efficiently.

Please click here to download our remote support tool.

How often does a cooling system need to be serviced?

To ensure reliable, efficient, and long-term operation of your cooling system, we recommend regular servicing at least once a year. An important part of this service is the leak tightness inspection, which helps detect potential leaks at an early stage and prevent unexpected breakdowns or unnecessary follow-up costs.

For larger systems or systems subject to intensive use, it may be advisable to carry out servicing twice a year to maintain optimal performance at all times.

We would be happy to advise you individually on the most suitable service intervals for your system. Please feel free to contact us – we will take the time to answer your questions and develop a maintenance concept tailored to your needs.

Can I service the system myself?

Only to a limited extent. Legally required tasks such as system servicing and leak tightness inspections may only be carried out by trained and certified specialists to ensure safe and compliant operation.

However, some basic care and cleaning tasks can be performed by the system operator. These include, for example, cleaning the condenser and checking and cleaning the water filters. Regularly carrying out these simple tasks helps maintain system efficiency and reduce wear.

We are happy to show you which tasks you can safely handle yourself and which should be carried out by a professional. Please feel free to contact us – we are glad to assist you.

What does maintenance by Quantor include?

Maintenance by Quantor is carried out in accordance with VDMA guideline 24186, Part 3 and is designed to ensure the long-term safety, efficiency, and reliability of your system.

As part of the maintenance service, we perform continuous target/actual comparisons and, if necessary, adjust the system control settings to achieve optimized and energy-efficient operation. All relevant results are documented, and you benefit from personal consultation with our qualified refrigeration specialists.

Please note that the maintenance service does not include cleaning of heavily contaminated systems. In addition, it is required that the cooling unit can be tested both under load and at standstill.

If repairs or the need for spare parts are identified during maintenance, we will inform you accordingly. These services are billed separately based on the applicable daily rates.

A safe and unobstructed access to the system on the day of maintenance is mandatory. A water change is not included in the scope of maintenance.

We are happy to explain the maintenance process in detail – please feel free to contact us, we will be glad to assist you.

Still have questions?

Our team is here for you in person!

Didn’t find the answer you were looking for in our FAQ?

No problem – our friendly support team will be happy to help you. Simply give us a call and speak directly with one of our experts.

We’ll take the time to understand your concerns and find a solution together.